Material Testing Capabilities

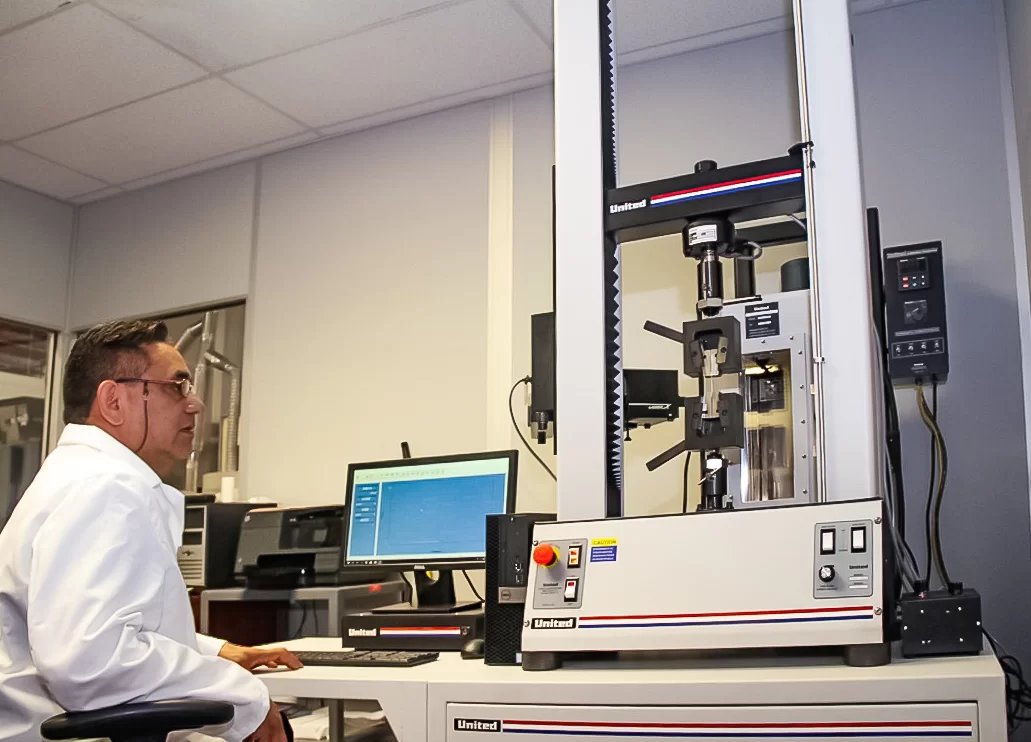

We provide extensive material testing capabilities to ensure ASTM, AMS, and MIL-spec compliance as well as proprietary spec compliance when required. Our capabilities are:

- Dimensional stability per AMS3678

- Moisture Content per ASTM D6980

- Specific Gravity per ASTM D792

- Zero Strength Time (ZST) per ASTM D1430

- Hardness Shore D per ASTM D2240

- Tensile properties per ASTM D638 and D1708

- Compressive properties per ASTM D695

- Percent Crystallinity of PEEKS per ASTM F2778

- Fourier Transform Infrared/Attenuated Total Reflection (FTIR/ATR) coupled with microscope services

- Scanning Electron Microscope coupled with Energy Dispersive X-ray Spectroscopy (SEM/EDS) services

- Thermal analysis services (DSC and TGA)

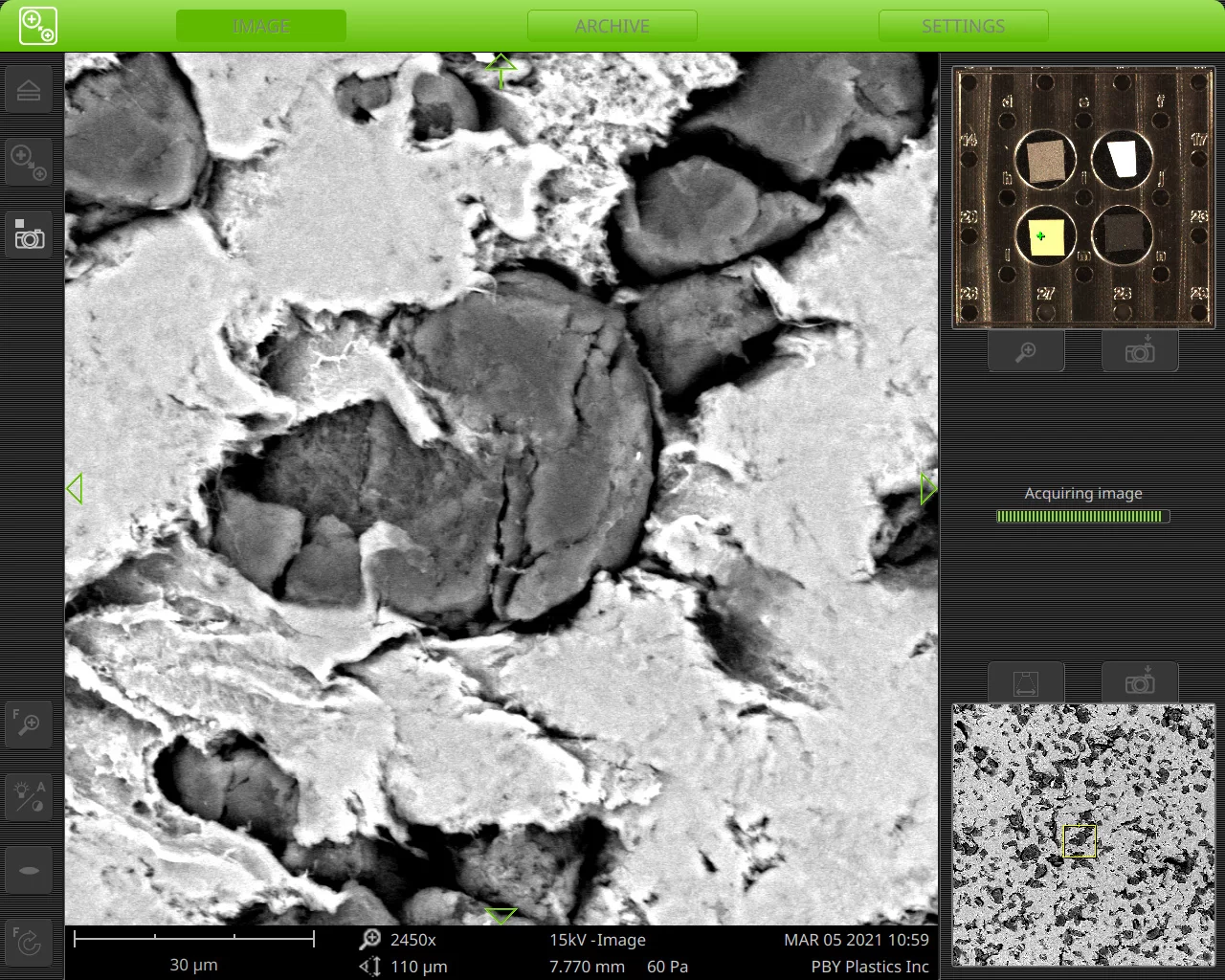

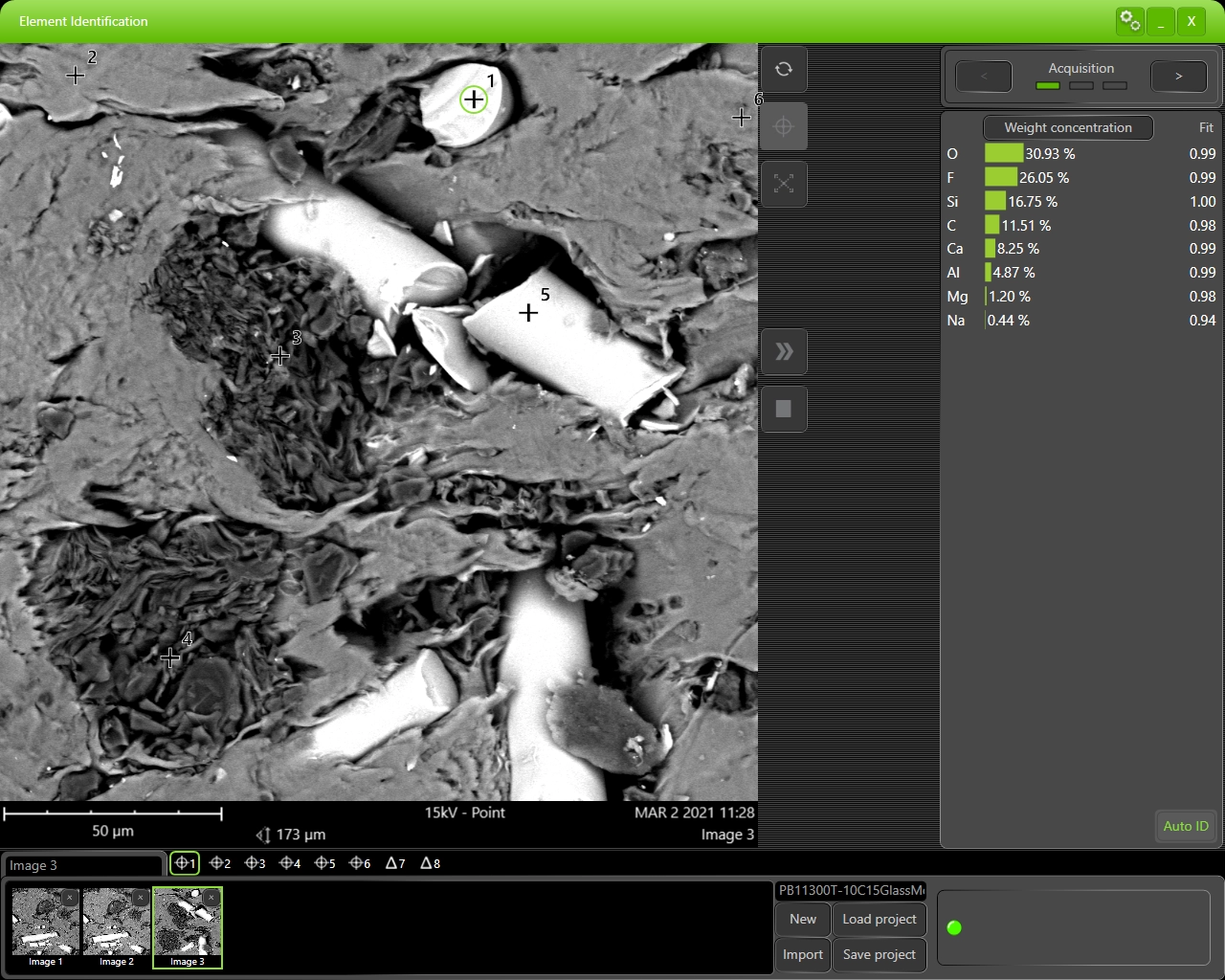

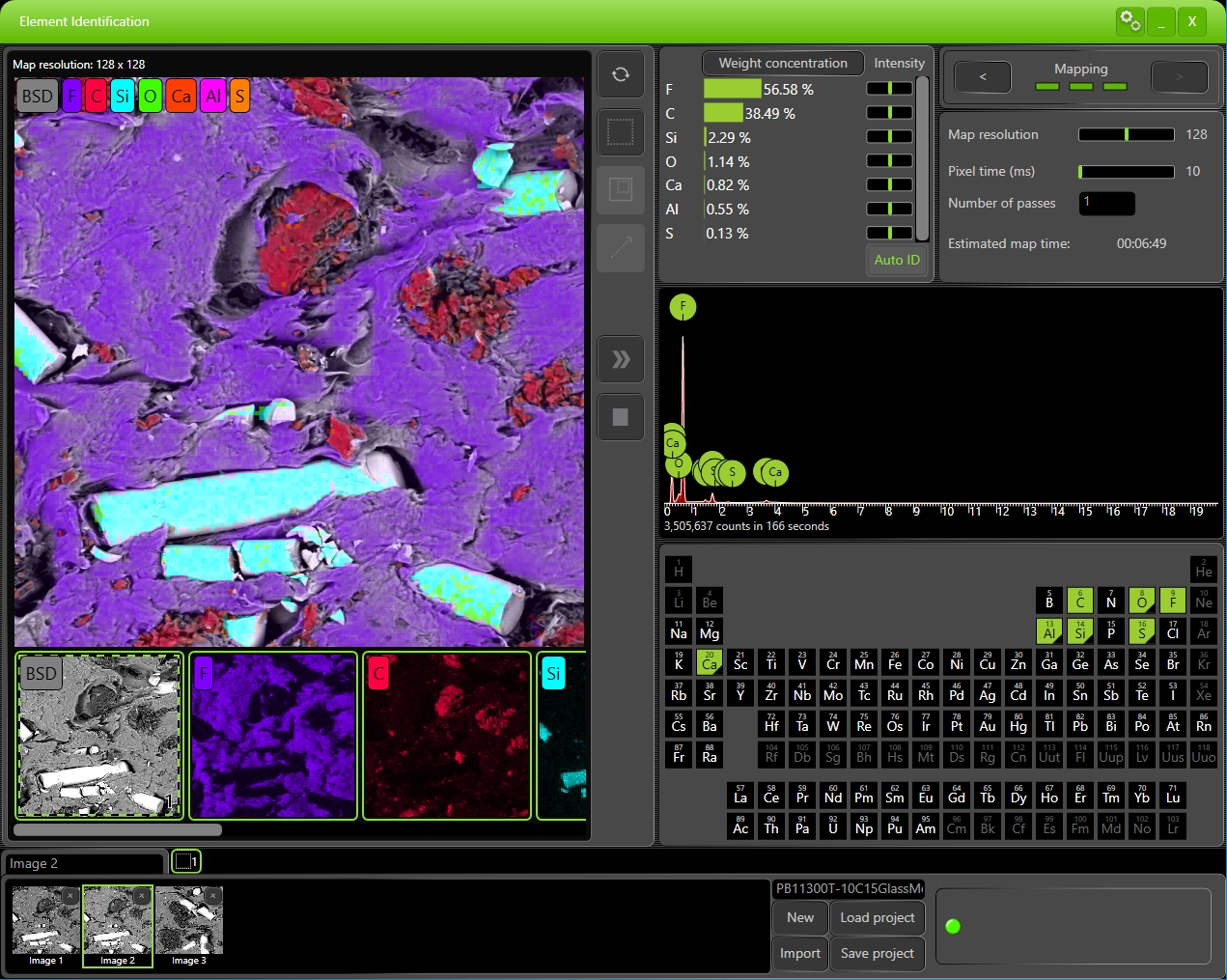

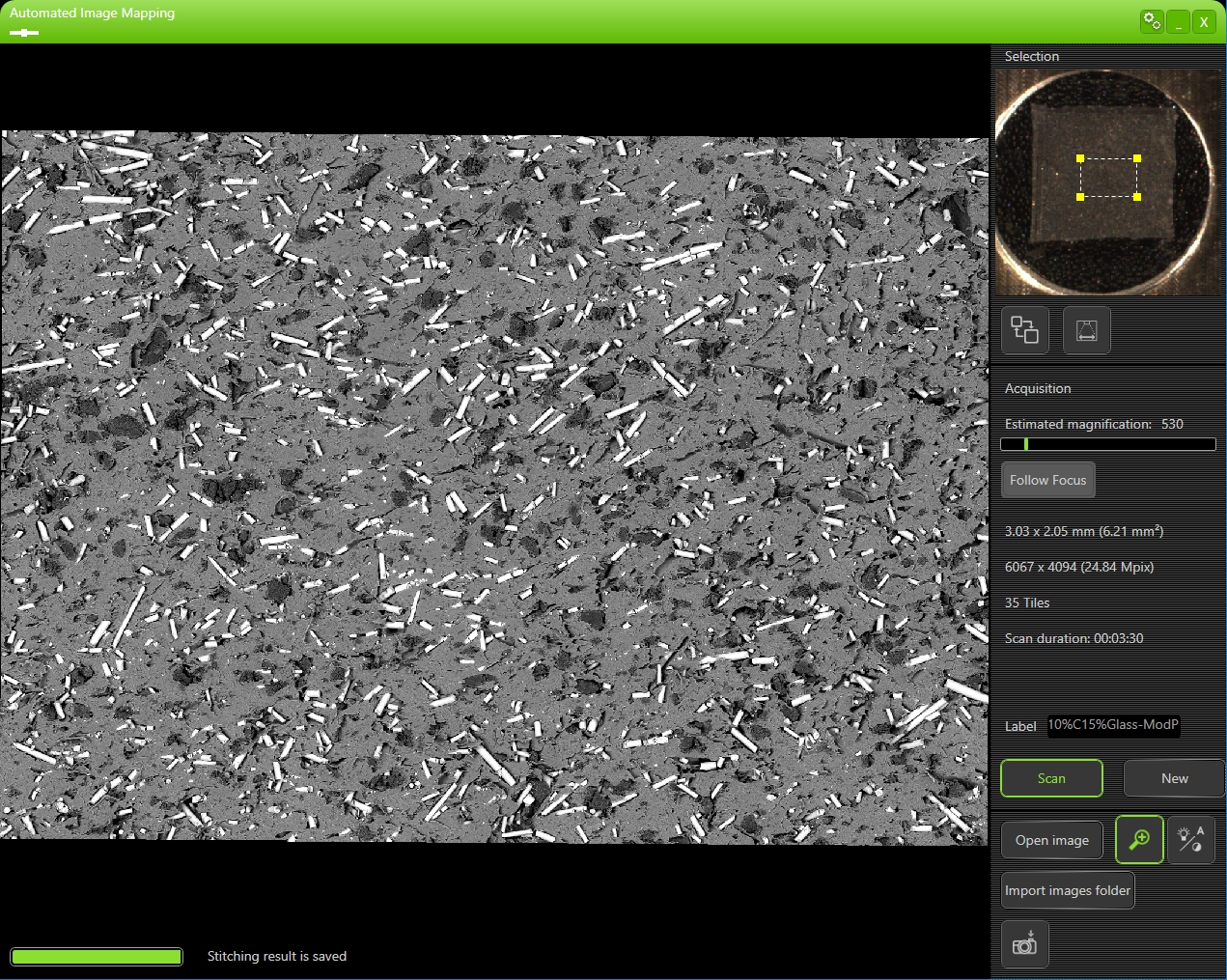

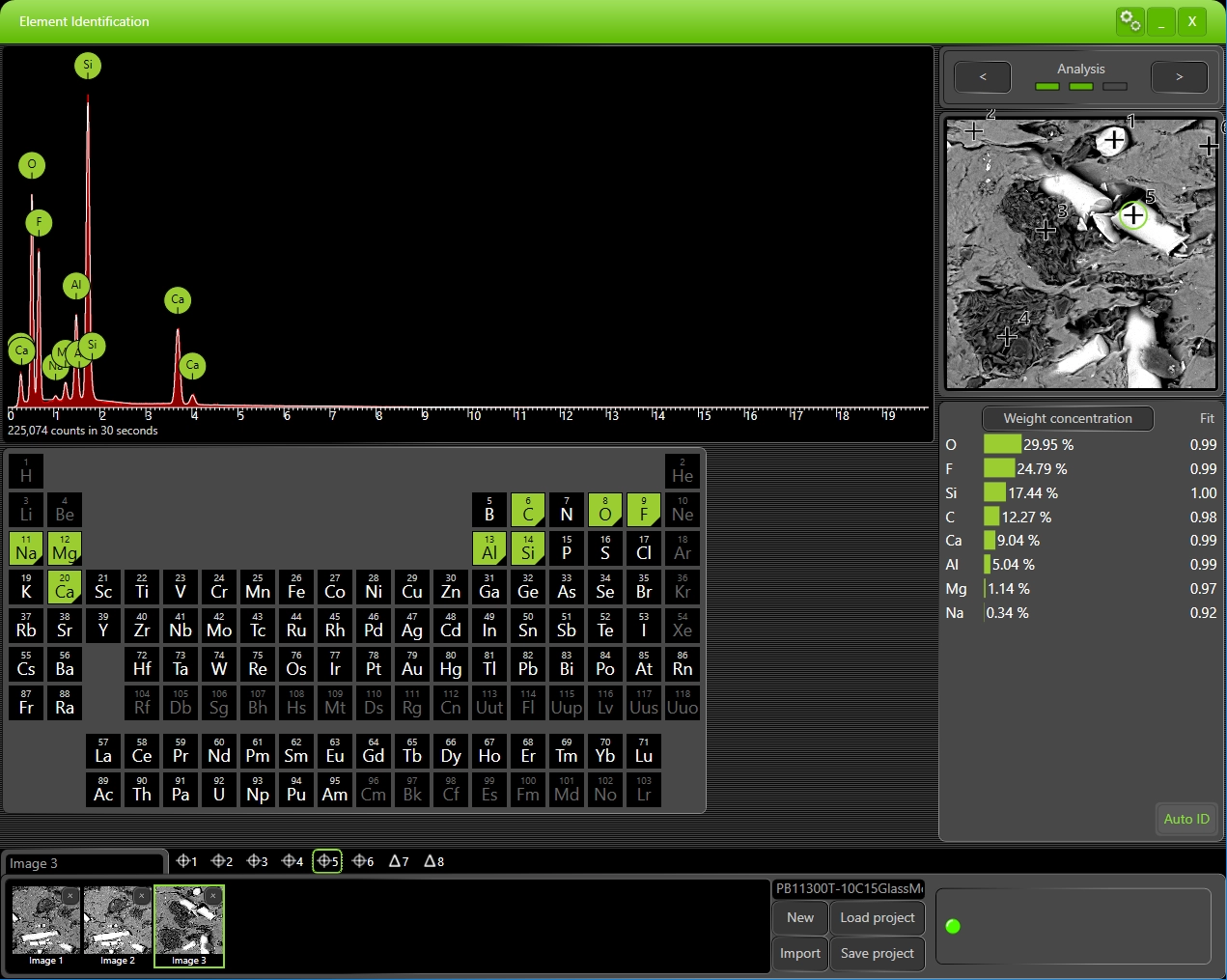

SEM and EDS Elemental Analysis

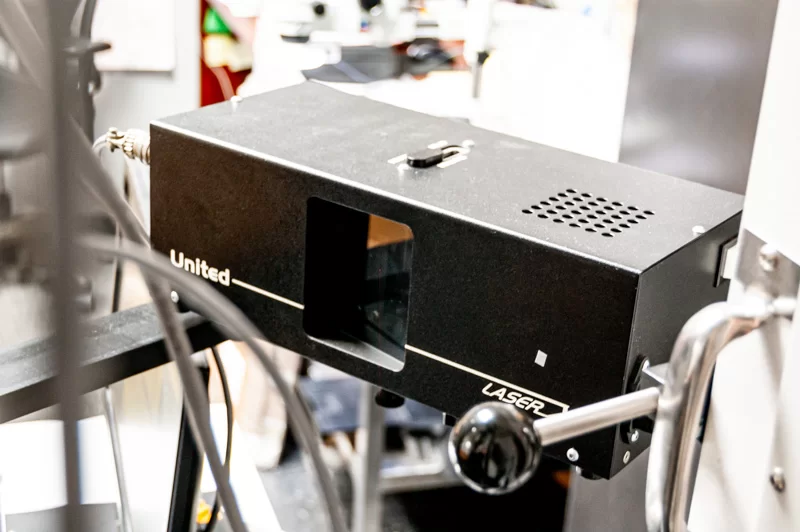

Our SEM and EDS elemental analysis hardware is equipped with 3-16x optical magnification and SEM magnification up to 100,000x with a resolution of 10nm.

We are able to provide excellent B&W backscattered and secondary electron images of various materials, including non-conductive samples without additional preparation, utilizing our low, medium, and high vacuum capabilities. We can image large areas using our automated image mapping software. EDS elemental analysis can be performed using different settings such as point, line, and/or mapping.

We do so at a sample size of 100mm x 100mm and a sample height of 65mm max.

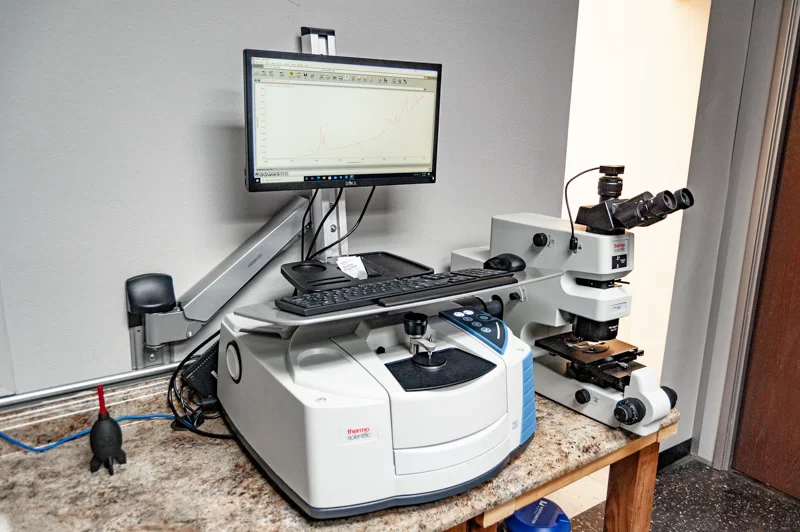

FTIR Microscope Particle Analysis

FTIR/ATR is used to obtain an infrared spectrum of absorption, emission, or reflection of a solid, liquid, or gas through a wide spectral range. Our Infrared range is from 4,000nm to 600nm. Mid-IR.

The infrared spectrum is the fingerprint of organic and inorganic materials.

FTIR/ATR is used for material characterization and verification of our incoming material.

Micro-size particle analysis and measurement of percent crystallinity of PEEK materials are possible when our FTIR is coupled with the microscope.

Thermal analysis services (DSC and TGA)

Thermal Analysis services (TGA/DSC) – Thermogravimetric Analysis (TGA) in DTA mode (DeltaT) is simultaneously coupled with Differential Scanning Calorimetry (DSC) in (mW) mode for fast enhanced results. When used in combination our thermal equipment is capable of determining filler content, decomposition temperatures, volatiles, oxidative and thermal stabilities, melting/crystallization behavior, glass transition temperatures, as well as specific heats capacity and transition enthalpies measurements. Sample size is 10-15mg.