Tour Our Facility

Learn more about our facility and our capabilities in providing high-performance plastics and materials. Our facility is equipped to solve your specific material needs.

Compression Molding Capabilities

We offer high-quality compression molded shapes and stock sizes.

Rod and Tube Sizes: 1.5" Diameters to 49" diameter tubes

Sheets: 12" x 12" to 36" x 36" sheets.

Custom Near Net Shapes Available

Class 1000 Clean Room | ISO 6

Our ISO 6 cleanroom (Class 1000 cleanroom) is equipped with state-of-the-art HEPA filtration systems to maintain air cleanliness during demanding plastics manufacturing processes.

Our compliant Cleanroom facilitates the requirements needed to manufacture plastics approved for medical devices and products that require no more than 1,000 particles (≥0.5 µm) per cubic meter of the inside air.

Materials Produced in Our ISO 6 Clean Room:

- Semiconductor assembly parts and components

- Virgin and Filled PTFE variants

- Modified PTFE

- PFA

- FDA regulated materials and NSF safe materials

Large Stock of a Variety of Compression Molded Shapes and Sizes

Sheet Thickness:

.010” thickness 6” x 6” to 2” thickness 36” x 36”

Tubing

◦From 1.5” OD x .50” ID to 49.50” OD

52” dia. Available upon request.

Rod/ Discs up to 39.5” dia.

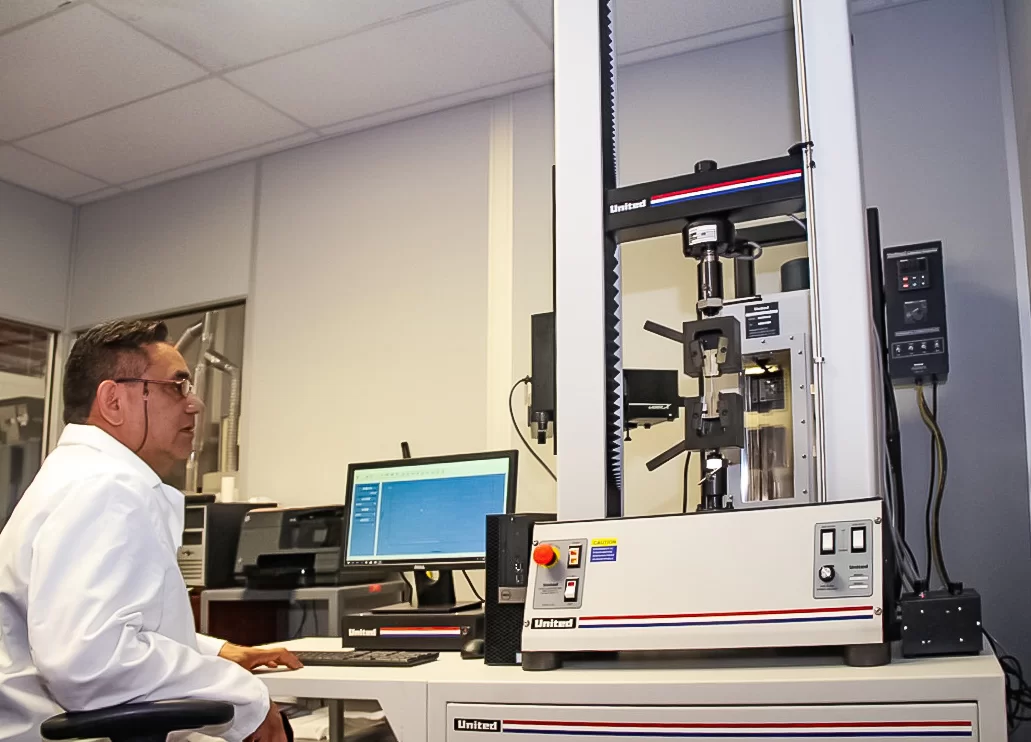

Material Testing Lab

- Moister Content Analyzer

- Hardness Shore D

- Tensile, compression, and three-point bending mechanical tester

- FTIR coupled with Microscope for particle analysis

- SEM coupled with EDS for elemental analysis