- Our Materials

- PB10000 Materials

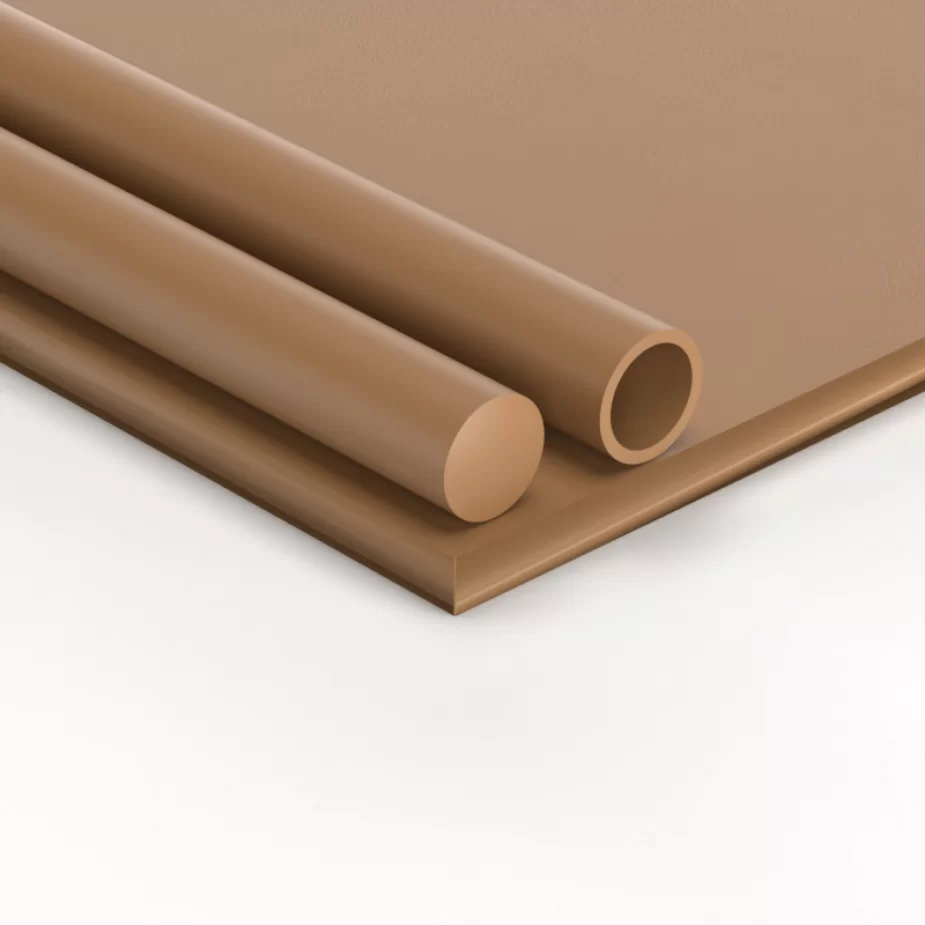

- Bronze

PB10000 SERIES

Bronze-Filled PTFE

Bronze is the most popular metallic PTFE filler. Bronze is an alloy of copper and tin, so it is attacked by acids and bases. Also, bronze oxidizes during the sintering process, but this has no influence on the quality of the compound.

Bronze is used in high amounts to increase the thermal conductivity and reduce the deformation under load when bronze-filled PTFE materials are subjected to load at extreme temperatures. Bronze-filled PTFE materials have very good abrasion resistance and compressive strength. Bronze-filled PTFE materials are typically used for bearing and wear ring applications.

PBY Material Codes:

PB10800 - 40% Bronze-Filled PTFE

PB10801 - 5% Moly 55% Bronze-Filled PTFE

PB10802 - 60% Bronze-Filled PTFE

Bronze-Filled PTFE Spec. Summary

| Property | Test Method | Units | 60 BRONZE | 40 Bronze | 5 Moly 55 Bronze |

|---|---|---|---|---|---|

| Color | - | - | Brown | Brown | Dark Brown |

| Specific Gravity | ASTM D792 | - | 3.850 - 4.154 | 2.950 - 3.350 | 3.500 - 4.000 |

| Hardness Shore - D | ASTM D2240 | - | 65 - 75 | 62 - 72 | 65 - 75 |

| Tensile Strength, min. | ASTM D4745 | PSI [MPa] | 1,800 [12] | 2,400 [16.5] | 1,500 [10.3] |

| Elongation at Break, min. | ASTM D4745 | % | 50 | 100 | 80 |

| Second Melt Peak Temp. | ASTM D3418 | °F [°C] | 621 [327] | 621 [327] | 621 [327] |

| Glass Transition Temp. | ASTM D3418 | °F [°C] | -143 [-97]; 246 [119] | -143 [-97]; 246 [119] | -143 [-97]; 246 [119] |

Material Available In:

Bronze-Filled PTFE Rods

Bronze-Filled PTFE Tubes

Bronze-Filled PTFE Sheets

Bronze-Filled PTFE Material Properties

-

Extremely hard-wearing material

-

Electrically conductive

-

Great deformation strengths

-

Good thermal conductivity

-

Extremely good wear properties of any filled PTFE

Typical Applications for Bronze-Filled PTFE

-

Bearing and wear rings

-

Often used in hydraulic systems, particularly superb as linear bearings, e.g., slides, gibs, guide ways

Bronze-Filled PTFE Requirements

PB10800 meets ASTM D4745 Type I Grade 10 and AMS 3678/14 requirements.

PB10801 meets ASTM D4745 Type I Grade 12 requirements.

PB10802 meets ASTM D4745 Type I Grade 11 and AMS 3678/6 requirements.

Bronze-Filled PTFE Material Data Sheet Downloads

PB10800 - Material Data Sheet

PB10801 - Material Data Sheet

PB10802 - Material Data Sheet

Bronze-Filled PTFE Spec. Compliance

References

- Wypych, George. Handbook of Polymers. 2nd Ed., ChemTec/Publishing, 2016.

- Ebnesjjad, Sina. Fluoroplastics Vol1 & Vol2. 2nd Ed., Elsevier Inc., 2015.

- Aerospace Materials Specifications for PTFE materials (AMS3678)

- American Society for Testing and Materials (ASTM) Standards