- Our Materials

- PB10000 Materials

- Glass Fiber

PB10000 SERIES

Glass Fiber-Filled PTFE

Glass fiber increases the wear and creep resistance of PTFE. It is the most common PTFE filler. Glass fiber-filled PTFE materials can be used in oxidizing environments, but be aware that glass fiber reacts with HF and strong bases.

Glass fiber-filled PTFE materials have a slightly higher coefficient of friction but better extrusion resistance than Glass fiber/Moly-filled PTFE materials. They are typically used in seal components for dynamic applications. They also prefer a lubricated environment and are used to seal against steel, stainless steel, and chromium-plated surfaces.

PBY Material Codes:

PB10302 - 15% Glass Fiber-Filled PTFE

PB10305 - 25% Glass Fiber-Filled PTFE

Glass Fiber-Filled PTFE Spec. Summary

| Property | Test Method | Units | 15 Glass Fiber | 25 Glass Fiber |

|---|---|---|---|---|

| Color | - | - | White | White |

| Specific Gravity | ASTM D792 | - | 2.150 - 2.250 | 2.150 - 2.250 |

| Hardness Shore D | ASTM D2240 | - | 60 - 70 | 60 - 70 |

| Tensile Strength, min. | ASTM D4745 | PSI [MPa] | 2,840 [19.6] | 2,270 [15.7] |

| Elongation at Break, min. | ASTM D4745 | % | 220 | 180 |

| Second Melt Peak Temp. | ASTM D3418 | °F [°C] | 621 [327] | 621 [327] |

| Glass Transition Temp. | ASTM D3418 | °F [°C] | -143 [-97]; 246 [119] | -143 [-97]; 246 [119] |

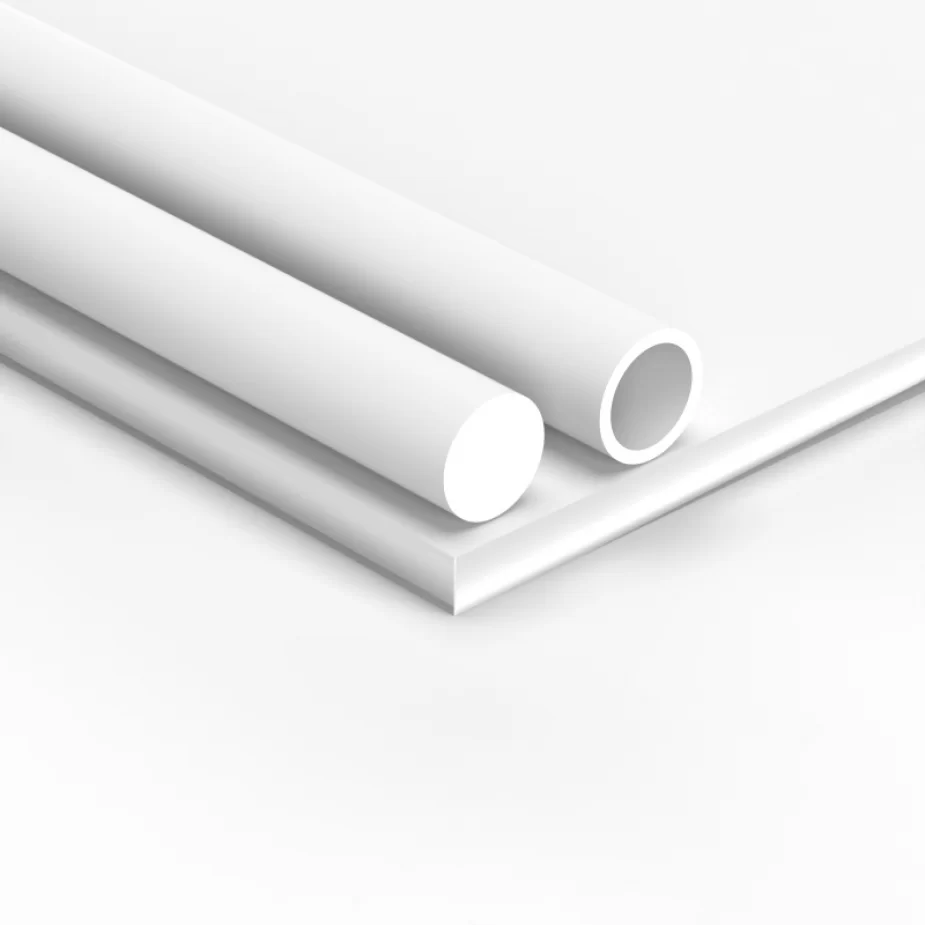

Material Available In:

Glass Fiber-Filled PTFE Rods

Glass Fiber-Filled PTFE Tubes

Glass Fiber-Filled PTFE Sheets

Glass Fiber-Filled PTFE Material Properties

-

Increases wear and creep resistance

-

Chemically Inert (Exceptions in HF and Strong Bases)

-

Performs well in oxidizing environments

Typical Applications for Glass Fiber-Filled PTFE

-

Wear Pads

-

Piston rings

-

Cookware coatings and rotating platforms

-

Containers and pipelines for chemicals

-

Machinery lubricant

Glass Fiber-Filled PTFE Requirements

PB10302 meets ASTM D4547 Type I Grade I requirements.

PB10305 meets ASTM D4745 Type I Grade 2 and AMS 3678/4 requirements.

Glass Fiber-Filled PTFE Material Data Sheet Downloads

PB10302 - Material Data Sheet

PB10305 - Material Data Sheet

Glass Fiber-Filled PTFE Spec. Compliance

References

- Wypych, George. Handbook of Polymers. 2nd Ed., ChemTec/Publishing, 2016.

- Ebnesjjad, Sina. Fluoroplastics Vol1 & Vol2. 2nd Ed., Elsevier Inc., 2015.

- Aerospace Materials Specifications for PTFE materials (AMS3678)

- American Society for Testing and Materials (ASTM) Standards