- Our Materials

- PEI

PB50000 SERIES

PEI

High-performance polymeric resins based on Imides, Amides and combinations thereof constitute our PB50000 series of materials, of which glass-filled PolyEtherImide (PEI) also known as Ultem® is the most common one and meets the requirements of ASTM D7293.

PB50000 materials are characterized by excellent thermal properties, good chemical resistance, inherent flame retardancy, and exceptional dimensional stability. Even though PB50000 materials preferred processing method is injection and extrusion molding, our compression molding material will also meet your expectations.

PBY Material Codes:

PB50302N - 30% Glass Fiber Filled PEI

PEI Spec. Summary

| Property | Test Method | Units | 30 Glass Fiber PEI |

|---|---|---|---|

| Color | - | - | Green/Brown |

| Specific Gravity | ASTM D792 | - | 1.470 - 1.550 |

| Hardness Shore D | ASTM D2240 | - | 84 - 94 |

| Tensile Strength, min. | ASTM D638 | PSI [MPa] | 16,000 [110] |

| Elongation at Break, min. | ASTM D638 | % | 2 |

| Tensile Modulus, min. | ASTM D638 | PSI [MPa] | 800,000 [5516] |

| Service Temperature High | - | °F [°C] | 340 [171] |

| Second Melt Peak Temp. | ASTM D3418 | °F [°C] | 426 [219] |

| Glass Transition Temp. | ASTM D3418 | °F [°C] | 423 [217] |

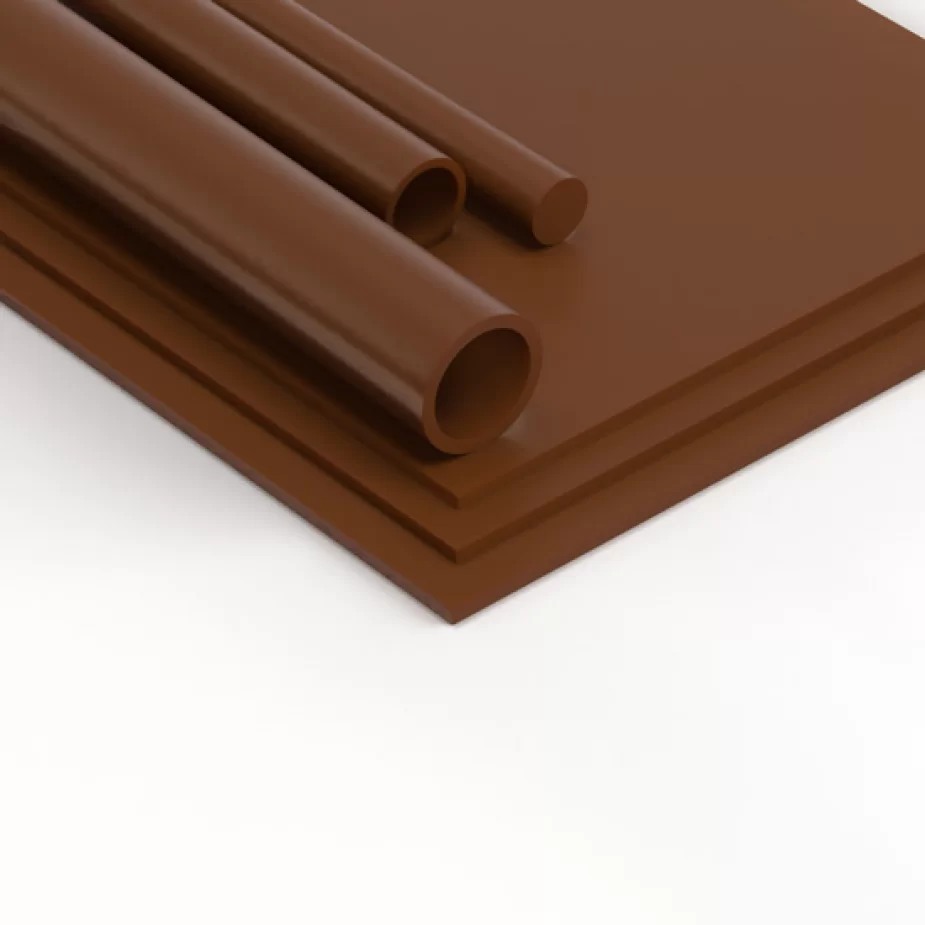

Material Available In:

PEI Rods

PEI Tubes

PEI Sheets

PEI Material Properties:

-

Extremely Strong Material

-

High dielectric strength

-

Easy to fabricate and machine

-

Resistant to hydrolysis when exposed

to hot water and steam -

Can withstand repeated sterilization cycles in a steam autoclave

-

Common Brand Names: Ultem® SUSTAPEI TECAPEI™

Typical Applications for PEI Plastics

-

Medical instrument components

-

Scientific equipment parts

-

Manifolds

-

Electrical connectors

-

Electrical insulation parts

-

Semiconductor equipment components

-

Chip test sockets

PEI ASTM Requirements

PB50302N meets ASTM D7293 Type 2 Class 1 Grade 3 requirements.

PEI Spec. Compliance

References

- Wypych, George. Handbook of Polymers. 2nd Ed., ChemTec/Publishing, 2016.

- Ebnesjjad, Sina. Fluoroplastics Vol1 & Vol2. 2nd Ed., Elsevier Inc., 2015.

- Aerospace Materials Specifications for PTFE materials (AMS3678)

- American Society for Testing and Materials (ASTM) Standards